1��、原材料的選擇:采光板的原材料主要是玻纖����、樹(shù)脂和表面貼膜以及色漿,選用優(yōu)質(zhì)的原材料是采光板質(zhì)量的根本決定因素�。 其中樹(shù)脂以間苯二甲酸(C8H6O4)為更好,化學(xué)穩(wěn)定性更適宜��,鄰苯二甲酸[C6H4(COOH)2]的價(jià)格低很多,但穩(wěn)定性不好���,容易造成成品板黃變老化�,因此不宜采用����。 玻纖更好不要用玻氈,因?yàn)槔锩婧z水��,同樣會(huì)造成黃變老化���,影響品質(zhì)���。表面貼膜非常重要,好的貼膜能有效防止紫外線并具有優(yōu)良的自潔性能��。

2�、成品過(guò)程:樹(shù)脂和根據(jù)需要加入的不同顏色的色漿均勻攪拌后輸送到生產(chǎn)線。 玻纖切絲灑落(不含膠水)或玻纖氈�、樹(shù)脂、貼膜一起進(jìn)入烤箱�。 烤制工藝:主要是溫度控制,在加工過(guò)程中會(huì)有數(shù)個(gè)溫區(qū)�,每個(gè)溫區(qū)的加熱溫度不一樣����,精確的控制溫度可以固化充分�����,這樣不易黃變老化��。好的生產(chǎn)線應(yīng)該有電腦控制溫度設(shè)備以及長(zhǎng)度足夠的烤箱���。

鋪設(shè)完畢以后����,預(yù)留出采光板的位置����,施工由檐口逐步往屋脊方向進(jìn)行���。采光板直接扣在鋼板的側(cè)波峰上����。

· 采光瓦施工時(shí)��,嚴(yán)禁腳直接踩在波峰上�����,以免采光板開(kāi)裂��。必須在采光板的橫向位置����,放置一塊1200mmx300mm{長(zhǎng)x 寬)防滑厚木板��,腳踩在其上進(jìn)行采光板的導(dǎo)孔和固定螺絲工作�。

Production process:

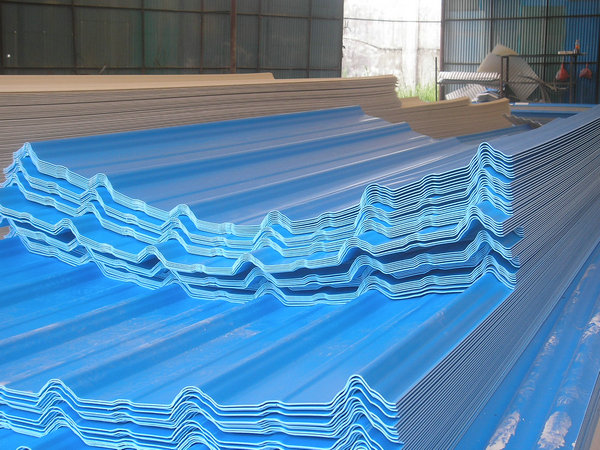

1, the selection of raw materials: the raw materials of the lighting board are glass fiber, resin and surface film and color pulp. The selection of quality raw materials is the fundamental determinant of the quality of the lighting plate. The resin with C8H6O4 (C8H6O4) is better, the chemical stability is more suitable, the price of phthalic acid [C6H4 (COOH) 2] is much lower, but the stability is not good, it is easy to cause the yellowish aging of the finished plate, so it is not suitable to adopt. Glass fiber better not to use glass mat, because it contains glue, will also cause yellowing and aging, affect the quality. Surface film is very important. Good film can effectively prevent ultraviolet radiation and has excellent self-cleaning properties.

2, the finished product process: the resin and the different colors of the color paste are added to the production line. Glass fiber shredded (without glue) or glass fiber felt, resin, film into the oven. Baking process: mainly temperature control, in the process of processing will have a number of temperature areas, each temperature area of the heating temperature is not the same, the precise control temperature can be cured fully, so it is not easy to yellow aging. Good production lines should have computer controlled temperature equipment and enough oven length.

Construction steps:

After laying, the location of the lighting panel is reserved, and the construction will proceed gradually from the eaves to the ridge. The lighting plate is directly buckled on the side wave peak of the steel plate.

The aperture of the lighting tile must be larger than the 6-9mm of the fixed screw diameter, so that it can be used as thermal expansion and cold contraction.

When the light tile and steel plate are longitudinally lapped, the 200mm overlap must be smaller, and two water stop zones are affixed.

When lighting tile is fixed, a good water washer should be used to make it between the screw and the lighting panel, so that it is waterproof and dust-proof.

After the water flooding washer is inserted into the screw, the electric drill is locked into the purlin to complete the fixing work of the lighting panel.

When the lighting tile is constructed, the foot should not be stepped on the crest directly, so as to avoid the cracking of the lighting panel. A 1200mmx300mm{long x wide wood board must be placed in the horizontal position of the lighting plate, and the foot must be carried on the guide hole and fixed screw for the lighting plate.